- Free shipping from zł750.00

- +48 71 321 07 95

- zamowienia@speed-bud.pl

Language:

Currency:

IC-2 injection station - FILAMOS

The injection station enables the production of cement grout and its application. It is a set of devices that allows for a wide range of tasks to be performed.

IC-2 injection station - FILAMOS

The injection station enables the production of cement grout and its application. It is a set of devices that allows for a wide range of tasks to be performed.

Advantages of the solution:

- smooth feeding - pressure regulation

- double-piston pump ensures continuous feeding of the mixture

- fast mixture preparation time - the mixing cycle of a full tank in the AM200 mixer takes approx. 1 minute

- simple and intuitive operation

- easy maintenance

- highest quality workmanship guarantees trouble-free operation, even in the most difficult conditions

- the devices are mounted on a compact structural frame.

Station components:

- IC120 double-piston pump - pump designed for the application of injection mixtures

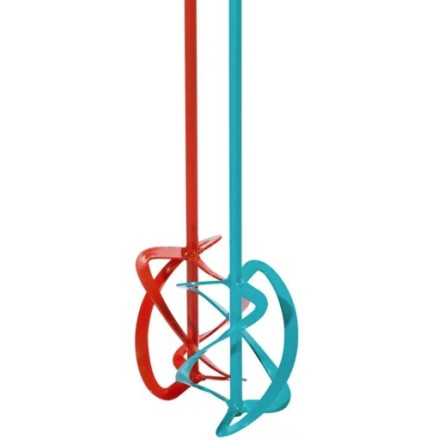

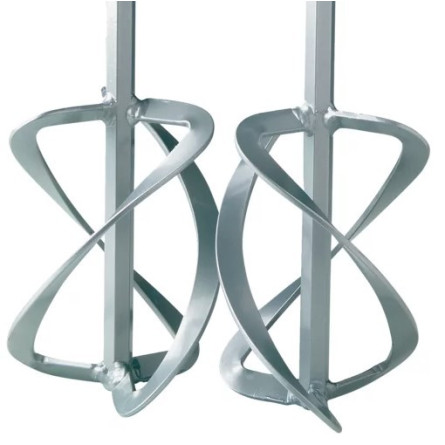

- Activation mixer (AM200) - designed for preparing high-quality grout

- Additional mixer - sustaining (DM200) - maintains a uniform mixture structure, even during technological downtime

- Structural frame

- 63A electrical switchboard.

Application:

Sealing micropiles, buildings, soil and foundation reinforcement, waterproofing, nailing (slope reinforcement) and many others.

Technical parameters of the equipment:

IC120 pump:

- maximum capacity: 120 l/min

- maximum pressure: 100 bar

- amount of mixture pumped in one cycle: 3 l

- maximum grain size: 0.5 mm

- maximum mixture density: 2 kg/l

- motor power: 5.5 kW

- Outlet diameter: DN25

- dimensions (L x W x H): 1420 x 720 x 1400 mm

- weight: 536 kg

AM200 activation mixer:

- tank capacity: 200 l

- working capacity: 150 l

- mixing capacity: 4 m³/hour

- motor power: 7.5 kW

- water inlet: 1''

- device dimensions (L x W x H): 1255 x 1030 x 1950 mm

- weight: 300 kg

DM200 additional mixer:

- usable capacity: 300 l

- mixer speed: 47 rpm

- motor power: 3 kW

- outlet diameter: DN40

- dimensions (L x W x H): 1010 x 800 x 1735 mm

- weight: 272 kg.