- Free shipping from zł750.00

- +48 71 321 07 95

- zamowienia@speed-bud.pl

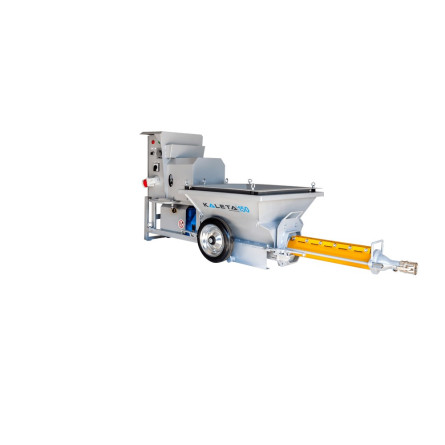

PFT G4 SMART plastering machine – with water pump

The most recognisable plastering machine model from the German company PFT. The machine is powered by 400V and can be used with a silo.

zł29,550.00 tax incl.

Available quantity: 0

PFT G4 X SMART PLASTERING MACHINE with water pump

catalogue number 00855897

Manufacturer's warranty – 12 months

Original plastering machine from the German company PFT – one of the most advanced plastering machines on the European market, known for its durability, reliability and ease of use.

PFT G4 X Smart is a new generation (gen25) plastering machine operating in continuous mode, designed for mixing factory-made dry machine-mixed mortars.

The device can be fed either from bags or directly from a silo using a PFT silo feeder. The mortar feed zone is separated from the mixing chamber and the pump. The material enters the mixing chamber through a diagonally mounted dosing wheel, which is driven by a separate motor and can be easily removed thanks to its central mounting.

Start-up and refilling with a new batch of material is possible at any time during operation.

New features and advantages of the G4 X Smart gen25 generation:

- removable compressor for easier transport

- reinforced cleaner and mixing pipe

- opening in the hopper for silo connection

- retrofit installation of a mortar level sensor possible

- improved ergonomics and transport handles

Application: Gypsum, gypsum-lime, cement, lime, lime-cement plasters, insulating plasters, mineral slurries, adhesive, reinforcing and grouting mortars, liquid screeds, masonry mortars, soundproofing compounds, self-levelling fillers and many others.

Technical data:

Pump motor: 6.05 kW, 400 rpm Feed wheel

motor: 0.75 kW, 28 rpm

Power supply: 400V, 50 Hz, 3 phases Screw

pump: PFT D6-3 Performer Feed

capacity: up to 35 l/min*

Operating pressure: max. 30 bar* Feed

distance: up to 30 m (DN25) / up to 50 m (DN35)*

Water pump: YES (AVO 500) Air

compressor: LK-250, 0.9 kW, 400 V, approx. 250 l/min Water

connection: 3/4" hose, min. 2.5 bar Water

flow range: 100 – 1000 l/h

*approximate data, depending on mortar, pump condition, hose cross-section and feed height

Basic equipment:

- RONDO DN25 10 m mortar hose with connectors

- ½" air hose 11 m

- Main gear motor 6.05 kW, 400 rpm with tilt sensor

- Feed wheel gear motor 0.75 kW 28 rpm

- Control cabinet with flow meter 150–1000 l/h

- LK-250 400V compressor with pressure switch (removable)

- Mixing chamber cleaner (reinforced version)

- Cleaner flat bar

- Plastering gun with 14 mm DN25 nozzle

- PFT D6-3 Performer screw pump

- Type "D" pump yoke with mortar pressure gauge

- BIONIK mixer

- Tool box

- Operating instructions

Dimensions:

- Filling height: 910 mm

- Hopper capacity: 145 litres

- Length/width/height: 1200 mm/720 mm/1530 mm

- Weight: 287 kg

Based on your current cart below are estimated shipping costs for this product. See further details in checkout. Price may vary depending on your cart and quantities.

| Carrier name | Shipping cost | |

|---|---|---|

|

DPD | zł19.00 |